CNC Swiss Turning

Precision Manufacturing

CNC Swiss Turning is a modern precision manufacturing process that can produce high quantities of extremely small components with speed and accuracy. Originally designed to produce the delicate pins and screws found in Swiss-manufactured watches, Swiss Turning machines are now widely used for precision manufacturing across a wide range of industries. From automotive to defense, to medical tools and electronics, the applications for CNC Swiss Turning are nearly endless.

How Does a CNC Swiss Turning Machine Work?

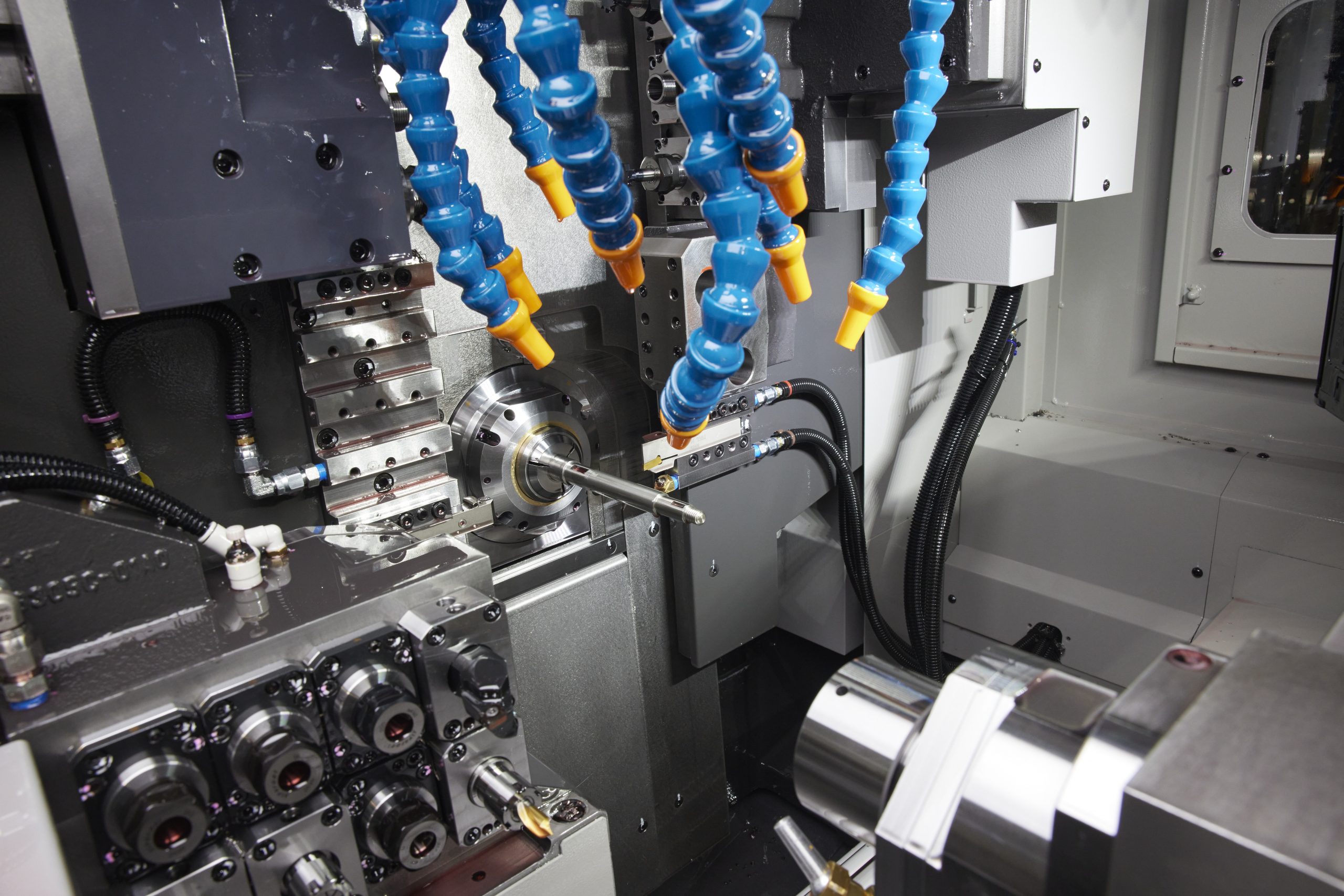

A Swiss Turning Machine works by rotating a piece of bar stock on a firmly supported spindle. Using Computer Numerical Control (CNC), pre-programmed computer software controls each individual movement of the bar stock and the manufacturing tools. The machine moves the tooling on multiple axes in correlation with the bar stock to complete the complex machining process.

At BIC Precision Machine Co., our Swiss Machines can handle up to 32mm/38mm capacity:

- Up to 32mm bar feed capacity

- Up to 38mm chucking mode of bar feed operation

What Are The Benefits of CNC Swiss Turning?

Complex Designs — CNC Swiss Turning machines can produce components with delicate and complex designs. Since the bar stock is well-supported during the tooling process, Swiss Turning can produce thinner walls, deeper cuts, and higher precision features than other manufacturing machines.

High Accuracy — Tight support of the bar stock virtually eliminates any extra force on the component that would impact the final manufacturing specifications. Even with extremely small components, CNC Swiss Turning can create products within tight tolerances.

Multitasking Manufacturing — In traditional CNC manufacturing, the bar stock typically rotates rapidly in a fixed position while individual tools are introduced one at a time to create the final product. CNC Swiss Turning moves the bar stock in and out of the work zone based on computer-generated manufacturing commands, allowing the machine to perform several tooling operations on the component simultaneously, including, milling, threading, drilling, boring, turning, and other custom finishing.

Optimal Cost — CNC Swiss Turning’s high precision machining and multitasking manufacturing enable our team to create higher quantities of products in shorter time frames. This makes the process more efficient from start to finish, which gives us the ability to save our clients time and money.