Additional Services

Throughout our company history, we’ve strived to set ourselves apart from our competition by becoming more than just another “outsourced machining vendor”. At B.I.C. Precision Machine, we continually seek to develop lasting partnerships with our customers. This continual effort has led us into a number of areas that help facilitate our customers’ production schedules and inventory methods.

We offer KanBan stocking programs for several of our customers, as well as accepting blanket orders for scheduled release dates throughout a given time period. By establishing strong partnerships with our vendors, we can provide a complete array of additional services including plating, heat treating, brazing, welding, balancing and ball burnish.

CMM INSPECTION SERVICES

Our Full Service Quality Department offers CMM Inspection services for our internal use, but also as a service to our customers. Our CMM reporting can provide customers with First Article Inspection and PPAP, as requested.

Our CMM provides reliable data to ensure your product meets all standards, design specifications, and tolerance levels. With our CMM inspection services, our technicians can accurately measure your product or part efficiently regardless of the size, material, or design complexity. The CMM inspection process is developed to help our customers produce the finest quality products and catch any errors before large-volume product runs are completed. Our priority is our customer’s success.

ASSEMBLY

We often machine several parts that can be combined into a subassembly. But, there are times customers prefer to receive a complete subassembly, rather than having the burden of assembling their parts in-house themselves.We conduct quality inspections to ensure assemblies are completed per customer requirements. You can trust B.I.C. Precision Machine to assemble your components correctly every time.

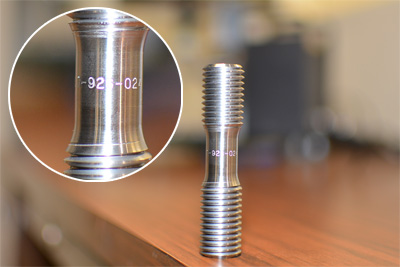

PART IDENTIFICATION

We offer part identification through several methods, per customer request. Whether it be logos that are required to be machined into a part, or simply a part number that is required to be stamped or etched, we are able to accommodate a majority of the requests that we receive.

We have a programmable marking machine that allows us to mark on flat surfaces as well as the outside diameter of smaller components. Serialization of parts is within our ability.

Engineering Services

Our Engineers and Machinists partner with you to create the most efficient process for designing and producing your parts. Our Engineering team utilizes the latest CAD software to design your new part to ensure your exact specifications are adhered to at each step of the development process. Our Engineering team will also advise you on the best materials for your part based on your intended application. Once our team creates the CAD drawing, we require your approval on the design before it moves to the manufacturing stage.

Do you have a special project in mind? Contact us today to get more information!