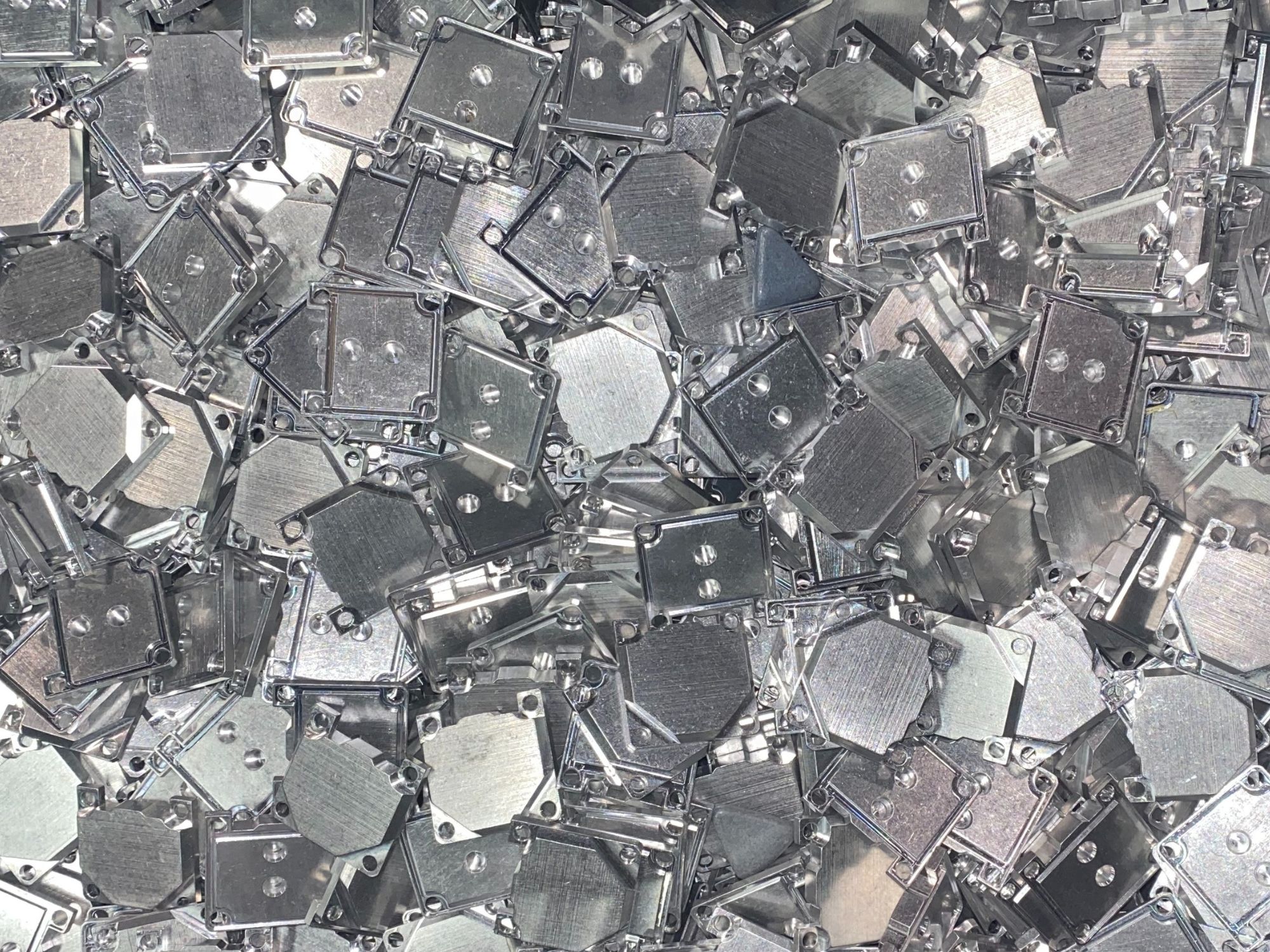

CNC Milling Services

Vertical & Horizontal Capabilities

At BIC Precision Machine, one of our top priorities is productivity. That is why we are equipped with several multi-axis capable machines, allowing for an added level of machining complexity.

Vertical Milling

Our multi-axis capability allows us to create your product efficiently, providing higher tolerances, faster part creation, and quicker turnaround times. Our Vertical Machining Centers provide us with a great project capacity, allowing us to meet varied customer needs at once. Our up to 50-station automatic tool changer keeps productivity at the forefront, cutting down on extra time and costs. With a wide range of machine sizes starting at 30” x 16” to our largest work envelope for vertical milling of 50” x 20” x 25”, we are happy to work with each client to determine their individual needs.

Horizontal Milling

Our Horizontal Machining Center allows for the combination of several routing steps. This makes it possible to run complex parts in the most efficient manner possible. This machining center combines the latest technology for tool breakage detection as well as spindle probe and tool setting utilizing the following specs:

- 2 station pallet changer

- Spindle speed of 10,000 RPM

- Sixty (60) station automatic tool changer

- A work envelope of 600mm (23.62”) diameter x 800mm (31.5”) high or 400mm (15.75”) square

At BIC

We pride ourselves on our capacity for low-volume runs, high-volume runs, and everything in between. With capacity capabilities ranging from 5 to tens of thousands, we are happy to work with each specific client’s requirements to bring their plans to life.